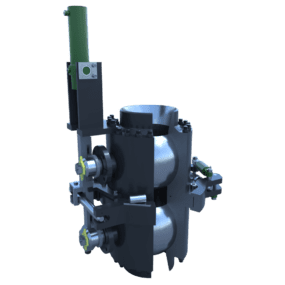

The use of swivel joints in loading arms are critical because of the extraordinarily high bending and axial load combination, due to the reach of the loading arm and wind forces. Our swivel joints are developed to withstand all these loads providing the best performance with virtually zero leakage and maintenance.