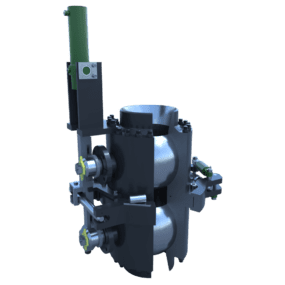

Hydraulic quick couplers offer the possibility of connecting the marine loading arm to the ship’s manifold by means of a single push button, from a remote distance. They are known in the market as very robust and straight forward connectors.

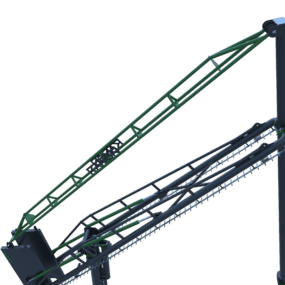

Our cryogenic solution is unique in its kind. It boasts a separate supporting structure bearing the loads of wind, a possible earthquake as well as the construction itself.

The product carrying part is integrated in the supporting structure, thus the pipe can shrink and expand to accomodate the temperature differences that occur in cryogenic applications.

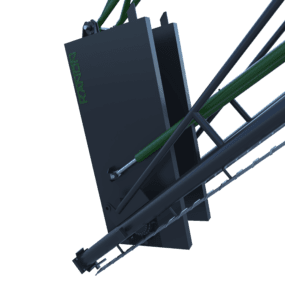

The traditional cables and wheels have been replaced by one of our unique features: a rigid pantograph system, designed to save maintenance time and, more importantly: weight.

Our cryogenic solution is unique in its kind. Want to know more? Download free to read about our products, service, installation, accessories, and more.

Hydraulic quick couplers offer the possibility of connecting the marine loading arm to the ship’s manifold by means of a single push button, from a remote distance. They are known in the market as very robust and straight forward connectors.

The ERC is part of our range of Emergency Safety Systems (ESS). Designed to provide best possible safety in fluid loading/unloading when using Marine Loading Arms. An ERC provides a fully automatic, safe and spillage free disconnection of the Loading Arm from the ship should the limits of the safe working envelope of the Arm be exceeded.

The use of swivel joints in loading arms are critical because of the extraordinarily high bending and axial load combination, due to the reach of the loading arm and wind forces. Our swivel joints are developed to withstand all these loads providing the best performance with virtually zero leakage and maintenance.

Double rotating counterweight, in order to keep both inboard & outboard section aligned and in perfect balance.

The parallel is the rigid link between the outboard section and the counterweights, a big advantage of the rigid structure is that the balance is set once in the factory and does not need to be adjusted in its entire lifetime.

You want to find the best solution for your challenge. Kanon cares about engineering the best loading equipment for you. From 40+ years of experience in tailor-made loading solutions, we help you make an informed decision. No strings attached. Transparency is key.

So, ask us, we will give an honest answer. Provide you with the information you need to make the right choice.

Are you interested in loading equipment, do you have a question or do you just want to say hi? Use the form below and we’ll have a chat.